Difference between revisions of "HPR Background Information"

(Added failure modes and stability info) |

(Added pie chart) |

||

| Line 27: | Line 27: | ||

There is one direction we care about when discussing motor retention, the y direction (axially). Simply put, the job of a motor retainer is to keep your motor from falling out of your rocket or allowing it to shoot through the nosecone upon ignition, resulting in a cato. Depending on the company, motor retainers have a couple different ways they work. For the slimline retainers used in the SSI Firestorm kit, the motor retainers use retaining rings. These rings are removable and are located on the lip of the the retainer. The purpose of the rings are to keep the motor from sliding out of the bottom while a lip on the body of the retainer prevents the motor from launching through the rocket's nosecone. For any 38mm motor being used in the 58mm Firestorm airframe, a motor adaptor is going to be used which has identical retaining rings, except smaller in diameter, to the motor retainer. | There is one direction we care about when discussing motor retention, the y direction (axially). Simply put, the job of a motor retainer is to keep your motor from falling out of your rocket or allowing it to shoot through the nosecone upon ignition, resulting in a cato. Depending on the company, motor retainers have a couple different ways they work. For the slimline retainers used in the SSI Firestorm kit, the motor retainers use retaining rings. These rings are removable and are located on the lip of the the retainer. The purpose of the rings are to keep the motor from sliding out of the bottom while a lip on the body of the retainer prevents the motor from launching through the rocket's nosecone. For any 38mm motor being used in the 58mm Firestorm airframe, a motor adaptor is going to be used which has identical retaining rings, except smaller in diameter, to the motor retainer. | ||

| − | |||

| − | |||

You can purchase/make motor adaptors which allow you to have a motor of a diameter that is smaller than the diameter of your rocket. For example: If one wanted to launch an L1 with a 54mm H motor but his or her rocket had an ID of 98mm, that person would purchase/make a motor adapter to keep the motor stable and restrained. Motor adapters consist of a tube that has the same ID as the motor's OD and uses centering rings to keep the motor centered between the airframe walls. If you are planning on using various diameter motors for the same airframe it might be a wise choice to invest in a motor retention system that allows the user to buy various components designed to work with different sized motors. | You can purchase/make motor adaptors which allow you to have a motor of a diameter that is smaller than the diameter of your rocket. For example: If one wanted to launch an L1 with a 54mm H motor but his or her rocket had an ID of 98mm, that person would purchase/make a motor adapter to keep the motor stable and restrained. Motor adapters consist of a tube that has the same ID as the motor's OD and uses centering rings to keep the motor centered between the airframe walls. If you are planning on using various diameter motors for the same airframe it might be a wise choice to invest in a motor retention system that allows the user to buy various components designed to work with different sized motors. | ||

| Line 69: | Line 67: | ||

== Failure == | == Failure == | ||

| + | |||

| + | [[File:MASA_flight_failure.PNG|400px|thumb|frame|right|Failure mode pie chart]] | ||

There is a fantastic NAR case study, "Launching Safely in the 21st Century", written by the Special Committee on Range Operation and Procedure which goes into rigorous statistical analysis of rocket failures. The following categories are common failure modes recorded from the fight log database of the Minnesota Amateur Spacemodeler Association (MASA, NAR 576): | There is a fantastic NAR case study, "Launching Safely in the 21st Century", written by the Special Committee on Range Operation and Procedure which goes into rigorous statistical analysis of rocket failures. The following categories are common failure modes recorded from the fight log database of the Minnesota Amateur Spacemodeler Association (MASA, NAR 576): | ||

| Line 104: | Line 104: | ||

LCO described the result as "No chute", it was potentially unsafe. | LCO described the result as "No chute", it was potentially unsafe. | ||

| − | + | These would be called "recordable incidents" in the jargon of safety professionals. When more than one failure occurred during a flight (e.g., unstable flight leading to lawn dart), the most severe event was recorded. | |

| − | These would be called "recordable incidents" in the jargon of safety professionals. | ||

| − | When more than one failure occurred during a flight (e.g., unstable flight leading to lawn dart), the | ||

| − | most severe event was recorded. | ||

== Motor Specs == | == Motor Specs == | ||

Revision as of 23:07, 8 March 2017

High power rocketry (HPR) is an essential and hands-on part of learning the fundamentals of rocketry.

NASA's online Beginner's Guide To Rockets will get you started on many of the basic principles governing rocketry. If you manage to make your way through all of these, you will understand the vernacular often used in rocketry. To learn more about rocketry, the theory behind it, and other useful things related to rockets, see So You Want To....

In addition that resource, here are some concepts compiled so you can quickly grasp what you need to know. If you are attempting an L1 certification, check out L1 Certification.

Jargon

Impulse and its Specificity

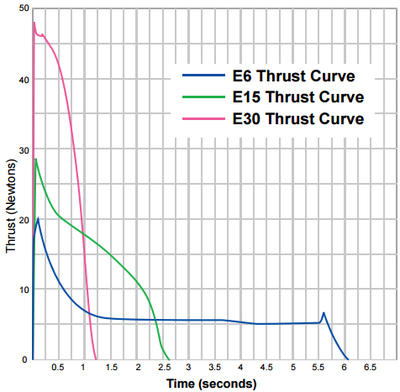

Impulse (or total impulse) is defined as equal to force multiplied by time - it is a measure of how powerful motors are, and can easily give you your change in velocity, Impulse / Mass, assuming no drag or gravity losses. (There will always be drag and gravity losses.) Total impulse can be thought of as the area under the thrust curve.

In the above graph, each of those three motors have the same total impulse (area under the curve), but with very different thrust profiles. The letter designation for each motor (e.g. in E15, H125, or M1250) are a measure of total impulse and each successive letter represents double the total impulse.

It turns out that impulse alone is not a gooad measure for rocket fuel performance; it is technically possible to use wood and air as rocket fuels, and to get an insanely large impulse by making the engine really big. That will never get you to space. Instead, rockets really care about a number called the specific impulse, defined as impulse divided by the mass of the propellant and the gravitational constant. This gives a far better picture of what constitutes a good rocket fuel, although there are definitely other considerations.

Motor Systems (DMS and RMS)

DMS stands for Disposable Motor System. These motors are one time use only, and are very easy to work with.

RMS stands for Reloadable Motor System. These types of motors are harder to work with, since they require the maintenance of a motor casing and proficiency in loading, cleaning, and reloading the casing. After purchasing the relatively expensive casing, one must learn how to assemble it with motor reloads. If not assembled properly, your rocket will most likely not make it through the flight. However, once you become good at assembling and using RMS, it is cheaper to merely have to purchase propellant each time you launch instead of an entirely new DMS motor.

Motor Retention (Positive or Otherwise) and Adaptors

There is one direction we care about when discussing motor retention, the y direction (axially). Simply put, the job of a motor retainer is to keep your motor from falling out of your rocket or allowing it to shoot through the nosecone upon ignition, resulting in a cato. Depending on the company, motor retainers have a couple different ways they work. For the slimline retainers used in the SSI Firestorm kit, the motor retainers use retaining rings. These rings are removable and are located on the lip of the the retainer. The purpose of the rings are to keep the motor from sliding out of the bottom while a lip on the body of the retainer prevents the motor from launching through the rocket's nosecone. For any 38mm motor being used in the 58mm Firestorm airframe, a motor adaptor is going to be used which has identical retaining rings, except smaller in diameter, to the motor retainer.

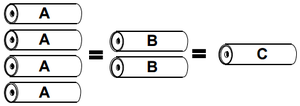

You can purchase/make motor adaptors which allow you to have a motor of a diameter that is smaller than the diameter of your rocket. For example: If one wanted to launch an L1 with a 54mm H motor but his or her rocket had an ID of 98mm, that person would purchase/make a motor adapter to keep the motor stable and restrained. Motor adapters consist of a tube that has the same ID as the motor's OD and uses centering rings to keep the motor centered between the airframe walls. If you are planning on using various diameter motors for the same airframe it might be a wise choice to invest in a motor retention system that allows the user to buy various components designed to work with different sized motors.

Some Quick Terminology Positive = not falling out the bottom.

Static Stability

Brief History

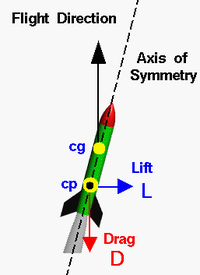

In 1958, G. Harry Stine published a simplified discussion of rocket stabilization geared towards model rockets using fixed fins on the rear of a rocket. The fins, if properly designed, provide a means of inducing a return to the desired flight path when a disturbance acts to rotate the rocket around its center of gravity (CG or c.g.). The air forces acting on a rocket can be thought of as all acting at a center of pressure (CP). He suggested a method of approximating the CP by constructing a cardboard cutout of the model and balancing the plan-form cutout.

The next advance in design came in 1966, when James Barrowman, then of NASA’s Sounding Rocket Division, presented a closed form algebraic solution to equations based on potential flow theory. The approximations used to achieve the closed form solution rely on the assumptions that the rocket (a) is traveling at a speed below that at which shock waves are formed (somewhat below the speed of sound), and (b) has a small angle between its flight path and the relative wind (i.e. a small angle of attack, or AOA). The Barrowman Equations continue to be widely used, both in graphical form and as the basis for hobby rocket design analysis software. From the "Launching Safely in the 21st Century: Final Report of the Special Committee on Range Operation and Procedure to the National Association of Rocketry", 2005.

Center of Gravity

An objects center of gravity is its (rigorously and mathematically defined) middle point. The force of gravity can be simulated to act here, and the object will tend to rotate about this point, making it crucial to finding rocket stability.

The relation of CG to your L1 rocket is its relation to the center of pressure (CP). For stable flight your CG needs to be towards the nosecone of your CP. If you determine that your CG is too close to your CP and need to move it forward because you can't change the position of your CP, a common method is to add some mass weight to your nosecone.

Center of Pressure

The center of pressure is the location at which we can model the aerodynamic effects as acting. In other words, the drag on the rocket acts at this point. If the center of pressure is below the center of gravity, then the downwards force of drag will keep the rocket upright, while a center of pressure above the center of gravity will flip the rocket. A CP and CG at the same point will create a neutrally stable rocket, meaning that any incidental forces could theoretically spin it. This makes the distance between the CP and CG critically important for determining whether flight will be safe and successful.

The main tool we have to change the center of pressure is the size of the rocket's fins - larger fins will bring the center of pressure lower down on the rocket, increasing its stability.

To calculate center of pressure, you can use the Barrowman equations (link to a slighty confusing example) or the cardboard cutout method.

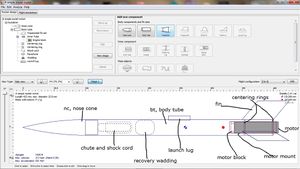

Another way to determine the CP of your rocket is to use a program like OpenRocket or RockSim. Both of these programs take all the information you input about your rocket and input into the Barrowman equations for you.

Calibers

A caliber is a unit of measurement defined as the diameter of the airframe. Calibers are used to measure the distance between the CP and CG - it doesn't make sense to solely measure based on distance, as a 3" difference on a 2" OD, 24" long rocket is very different from a 2" difference on a 10' long, 6" OD one.

Calibers measure the length between CP and CG allowing for a much more fair comparison between different rocket sizes. It would be correct to say, the CG is 2 calibers away from the CP.

As a rule of thumb, having your CP 1.5-2 calibers in front of your CG is considered good, while numbers outside of that range tend to be either under-or-over-stable.

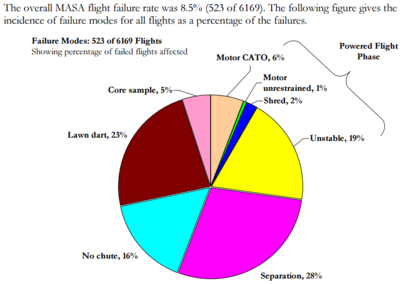

Failure

There is a fantastic NAR case study, "Launching Safely in the 21st Century", written by the Special Committee on Range Operation and Procedure which goes into rigorous statistical analysis of rocket failures. The following categories are common failure modes recorded from the fight log database of the Minnesota Amateur Spacemodeler Association (MASA, NAR 576):

Unstable. The rocket flies with at least part of the boost phase in a nose-down attitude. For the purposes of this study, based on the goal to characterize unsafe events, comments such as "kind of unstable" were not counted, nor were "horizontal", "cruise missile", or "coning" flights (unless they resulted in a crash; see below).

Lawn dart. The rocket descends in ballistic flight with the nose cone still on. This category includes "No ejection" and a few "power prangs". Some rockets are designed to do this and these flights were not counted. Boosters on two stage rockets also did this.

Separation. The rocket descends in multiple parts with at least one part not slowed by a recovery device. For the purposes of this study, the few flights with a comment of "stripped chute" were included here. The unplanned ejection of motor casings should also have been collected here, but MASA LCOs almost never recorded them as outcomes.

Motor CATO. The motor failures catastrophically at ignition or during boost. The nature of the CATO (spit nozzle, forward closure failure, blow by, etc.) was sometimes recorded, but not consistently.

Core sample. The rocket descends in ballistic flight, but with the nose cone off the rocket and acting as a (not very effective) streamer. These events typically have lower impact speeds, and higher surface areas at impact, than do lawn darts.

Motor unrestrained. The motor exits the rocket at ignition or during boost (thankfully, this was rare).

Shred. The rocket comes apart during ascent, other than by design.

No chute. The rocket descends without a recovery device deployed, but is not ballistic. This category does not include chutes that were described as merely tangled, although it is likely that some LCOs write "no chute" in those circumstances. The rationale here is that if the LCO described the result as "No chute", it was potentially unsafe.

These would be called "recordable incidents" in the jargon of safety professionals. When more than one failure occurred during a flight (e.g., unstable flight leading to lawn dart), the most severe event was recorded.

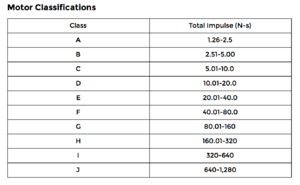

Motor Specs

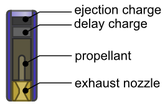

Solid rocket motors have a fairly standardized labeling system. On the casing (or reload) itself there is a three-part code which denotes what the total impulse range is, the average thrust, and the delay grain length. All these numbers are in standard metric units.

The letter designation represents the total impulse. Each letter category represents double the total impulse of the previous letter category.

Motor classification table:

Motor Designation Breakdown

To better understand how to read a motor label lets take an example:

Aerotech H550ST-14A

Here is the spec sheet for this motor[1]. This is the motor that SSI uses for its L1 certification launches.

- H: the letter designating the impulse range. For an H this is from 160 Ns - 320 Ns.

- 550: denotes that the motor's average thrust is 550 N.

- ST: denotes what type of propellant is in the casing. In this case, ST stands for "Super Thunder". Aerotech has various names for their different types of propellants, however, often these names are only denoting the color of the flame rather than the chemical compounds that it is made of.

- 14: denotes that the motor will fire its ejection charge 14 s after burnout unless it is adjusted, as indicated by the A. Motor delay times can be adjusted with a motor delay tool (otherwise known as a proprietary screwdriver, here is a link to buy one[2]).

Recovery

Recovery is the second stage of a simple non-complex rocket, aka basic L1. Although it would seem like the largest percentage of failure would happen during ascent, 75% of failed rockets are a result of a faulty recovery system. Common points of failure for an L1 are: the parachute did not deploy out of the airframe, the parachute deployed too soon before or too far after apogee, line tangling, and too quick of a descent. All of these aspects are things that you should consider when compiling your recovery system.

For L1 all a rocketeer needs is single stage deployment. Simply put, only a main parachute is required to bring the rocket safely back to the ground. Because it is single stage, the parachute should be ejected as close to apogee as possible to prevent unnecessary damage to the rocket. Apogee is the highest point of a rocket trajectory, where the vertical velocity is momentarily zero and the rocket transitions from ascent to descent. This is the point at which the rocket is moving slowest and thus is the most ideal for deployment of a parachute.

For typical L1 rockets, after the motor burns through its main propellant, it burns through a delay grain. This is a slow-burning section at the end of the motor which acts as a timer. Once it has burned through the delay grain, the flame front ignites an ejection charge loaded in the charge well at the front of the motor. This ejection charge, typically black powder, pressurizes the body tube of the rocket and forces the nose cone out, along with the parachute. To test whether your nose cone has the proper fit (tight enough to stay on during flight but loose enough to eject for recovery), hold the back end of your completed, and unloaded, rocket to your mouth and blow hard with a good seal. The nose cone and parachute should both pop out. If you are incapable of doing this, another test can be done by vigorously shaking the rocket by holding the nosecone. The nosecone should separate from the rocket by doing this.

Simulations

It is always important to know what your rocket will do (assuming that things go according to plan), and we use a program called OpenRocket to find the flight profile of our rockets. The program is free, and can be found here[3]

OpenRocket is quite easy to learn, and is quite accurate for sub-Mach rockets (those that fly faster should use RasAero to model drag forces.) OpenRocket includes ascent, including a massive database of thrust curves, as well as a simulated descent using the parachutes included in the rocket. If used properly, it can output data from height of apogee to time of flight to drift distance, all of which are incredibly useful while designing your rocket. (Hint: the center of pressure calculation is extremely important.)

One other program of note is called FinSim, which can model possible vibrations within fins. If unchecked, these vibrations can grow and shear the fins off, likely dooming the rocket. The program is required for transonic and supersonic flights, and can be found here[4]